The octane number of a fuel indicates its resistance against self-ignition (detonation).

Two hydrocarbons are used as a reference:

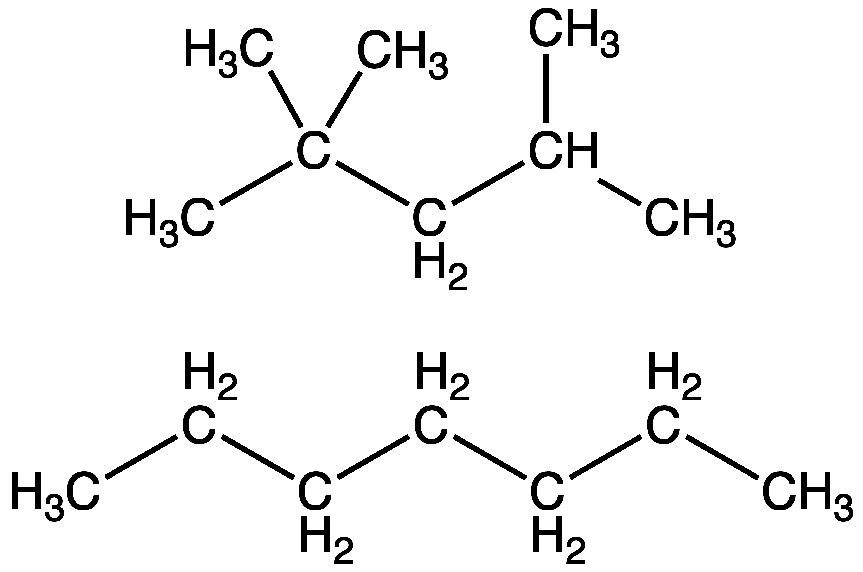

- iso-octane (or more precisely: 2,2,4 trimethyl pentane, C8H18),

- heptane (also called n-heptane, C7H16)

The two have rather different properties when it comes to self-ignition - iso-octane has a high resistance to self-ignition, while heptane has a low resistance to self-ignition. If you heat up the vapor of these hydrocarbons enough and put it under sufficient pressure (as in an internal combustion engine), it will eventually ignite (or burn) by itself. That's not wanted characteristic! The fuel in engine has to ignite in precise timing by spark, not by self-ignition before that.

|

| iso-octane (above) and heptane (bellow) |

This is where the octane number comes into the picture. To determine the octane number of a fuel, it is burnt in a special (test) reference engine, of which the operational parameters can be varied (most importantly, the compression ratio). The compression ratio of the engine is increased until the engine starts knocking. Then, it is determined what mixture of octane and heptane will behave the same with regard to knocking as our fuel under test. To give an example: say our fuel has the same knocking behavior as a mixture of 87% octane and 13% heptane. Then our fuel has an "octane number" of 87.

The question then is how can you have fuel that has an octane rating higher than 100? Fuels with these octane ratings of 100+ are actually used in racing and in the world of aviation. Obviously, the octane number of these fuels cannot have been determined with our reference engine. The short answer is that these ratings are determined by extrapolation.

Octane ratings in USA and Europe

The next confusing thing is that octane ratings in the USA and Europe differ significantly. In the USA, you can typically buy regular (87 octane), medium (89 octane), and premium (91-94 octane). In Europe, you can typically buy 95, 98 and 100 octane fuel. There are two different sets of conditions under which the octane number is determined. The first set of conditions simulates low load conditions, sort of corresponding to everyday, regular driving conditions and the number that results is called the Research Octane Number, or RON. The second set of conditions simulates a higher load on the engine and the number that results is the Motor Octane Number, or MON. Typically, RON is higher than MON for 10 octanes. In Europe, the octane number posted is determined by the RON method. In the USA, the number posted is according to the "AKI=(RON+MON)/2" method (average between RON and MON) also called AKI (Anti-Knock Index).

Ignition moment

Inside an internal combustion engine, the air-fuel mixture should ignite when the spark plug produces a spark, and not any sooner. If the air-fuel mixture ignites too soon, very bad things happen. Temperatures inside the cylinder spike and the piston and valves will be damaged severely. This phenomenon is called knocking, pinging (after the sound that it produces), pinking, or pre-ignition. More precisely, knocking occurs when combustion of the air-fuel mixture starts at more than one point in the combustion chamber. Pre-ignition seems to describe the situation when the air-fuel mixture ignites even before the spark plug produces a spark. Pre-ignition is even worse than knocking, apparently.

As the piston moves up and compresses the air-fuel mixture, it will reach a certain highest point. The air-fuel mixture is compressed to the maximum at this point. This point is called Top Dead Center or TDC for short. This is the ideal time for the spark plug to fire and to ignite the air-fuel mixture, since the effective work will be maximal. This would be the case if the air-fuel mixture would ignite instantly. However, it takes a certain amount of time before all of the air-fuel mixture is burning and the pressure will be maximal. So, the ideal time to ignite the air-fuel mixture is a little before the piston reached TDC. The amount of this time is called spark advance, and it typically specified in degrees, one axle rotation being 360 degrees.

The time for the air-fuel mixture to combust is constant for all practical means and purposes. It is typically independent of the RPM of the engine. Unfortunately, the piston will be moving up faster if RPM increases. So spark advance, or ignition advance, is dependent on the RPM. This is basically taken care of by the ignition timing mechanism: the higher the RPM, the more ignition timing will be advanced. In older vehicles it is accomplished by mechanical means, in newer cars the electronic ignition timing system takes care of it (and can do so more accurately). For a given RPM, there is an optimal ignition timing. Any sooner or later, and the engine will not be performing optimally.

Modern internal combustion engines have devices called knock sensors. Basically these devices "listen" to the engine and detect if there is any knocking going on. If so, the ignition timing is adjusted to stop the knocking. Typically this is achieved by retarding the ignition timing. This means that the spark plug fires slightly later than the optimal moment. This causes the air-fuel mixture to reach maximum pressure when the piston is already on its way down. This causes the piston to get slightly less of a "push" than under optimal circumstances, causing the temperature in the cylinder head to drop slightly, and thus reduce the likelihood of knocking on the next cycle. This retardation continues until knocking stops.

The question might be, why not advance the timing rather than retard it, if there is an optimum ignition moment? If the spark plug sparks before the optimum moment, the piston will still be moving upwards when the air-fuel mixture burns. This would be very bad for the engine. For example, it is very possible that connection rods may become bent. This ignition retardation causes engine power to drop. This is where the following widespread misconception comes from: If ignition retardation causes power to drop, then ignition advance must cause power to rise. So, an engine with a sophisticated Engine Management System can produce more power on high octane fuel.

So there is an optimal ignition moment. Assuming that the vehicle manufacturer has designed the engine properly (i.e. to run without knocking, even under high load, with the recommended fuel), then there is no benefit to be had from higher octane fuel, except maybe for the minimal difference in heating value

In other words, an Engine Management System can only improve performance with higher octane fuel if the engine is knocking when running on the recommended grade! So, that would mean that the fuel recommendation is wrong! This seems rather unlikely, also given the fact that engine manufacturers are typically quite conservative when recommending octane numbers, i.e., its better to recommend a fuel grade that is slightly higher than necessary than to have customers ruin their engines.

Why octanes?

So, why do the guys at the race track put 100+ octane fuel? They use modified engines. If you modify an engine by putting another cylinder head on, then yes, you may have increased the engine's octane requirement, and therefore a higher octane fuel is needed to prevent knocking. If you added or modified a supercharger so that the pressure and temperature in the cylinder head are higher than what the engine was designed for, then yes, again, you have increased the octane requirement. Note that the higher performance at the racetrack is not caused by the higher octane fuel. The higher performance is caused by engine modifications, which then require a higher octane fuel to prevent knocking. In engines with carbon buildup on pistons or in the combustion chamber, high octane fuel can provide some benefit. Deposits can reduce cylinder volume at top dead center, effectively increasing the compression ratio. This alone can lead to engine knock. The deposits can also become hotspots that preignite the mixture, leading to engine knock.

Bottom line is: if your engine is not knocking (which should be the case with the recommended fuel), then putting higher octane fuel in will not give you better performance. Again, with the caveat that the possible higher heating value might give a very small possible increase.

So there are two main misconceptions about high octane fuel:

- Contains higher energy content (increasing power and fuel economy)

- Formulated with higher-quality additives (increasing engine cleanliness)

Octane has nothing to do with energy content or quality – it’s a measurement of the gasoline’s ability to resist engine knock. Higher octane denotes greater knock control. Additive can be added to gasoline or not but it has nothing to do with octane number.

Nema komentara:

Objavi komentar